Understanding different offshore wind foundations

Looking below the water line for the benefits and challenges involved in choosing the right substructure.

Offshore wind energy is a rapidly growing sector in the global transition to renewable power. While the towering turbines above the sea are the most visible components, the foundations beneath the surface are equally critical.

These structures must support extreme loads, endure harsh marine environments, and be cost-effective over decades. The choice of foundation depends on water depth, seabed conditions, and turbine size. Here are the main types of offshore wind foundations and their respective pros and cons:

1. Monopile foundations

Monopiles are the most used foundation type, especially in shallow waters ranging between 5m to 55m. They consist of a single large steel tube driven deep into the seabed.

Case study: Hornsea Project One, UK

Hornsea One, developed by Ørsted, is one of the largest offshore wind farms in the world. Located off the Yorkshire coast, it uses monopile foundations for its 174 turbines.

Pros:

- Simple design and relatively low cost

- Quick to manufacture and install

- Proven technology with extensive operational history

Cons:

- Limited to shallow waters

- Installation noise can disturb marine life

- Less suitable for larger turbines or complex seabeds

2. Jacket foundations

Jacket foundations are lattice-like steel structures anchored to the seabed with multiple piles. They are typically used in water depths of 30m to 100m.

Case study: Beatrice Offshore Wind Farm, Scotland

The Beatrice Wind Farm in the Moray Firth uses jacket foundations for its 84 turbines, chosen for their suitability in deeper waters (~45m).

Pros:

- Strong and stable in deeper waters

- Efficient use of materials for large turbines

-

Better suited for uneven seabeds

Cons:

- More complex and expensive to fabricate

- Requires specialised vessels and longer installation times

3. Gravity-based foundations (GBFs)

These are massive concrete or steel structures that rest on the seabed relying on the ballast weight for their stability. Their use ranges from 15m to 40m.

Case study: Thornton Bank Wind Farm, Belgium

Thornton Bank Phase I used gravity-based foundations due to the rocky seabed and relatively shallow water depth (~27m).

Pros:

- No need for piling—quieter and less disruptive

- Suitable for rocky, uneven, or hard seabeds

- Long lifespan and low maintenance

Cons:

- Very heavy—requires extensive seabed preparation

- High transport and installation costs

- Limited to relatively shallow waters

4. Suction bucket foundations (SBJs)

Suction buckets are large, inverted steel cylinders that are embedded into the seabed using pressure differentials. Operability depth ranges from 15m to 60m. For shallower depths the suction pressure required for installation becomes insufficient due to limited hydrostatic head.

Case study: Borkum Riffgrund 1 & 2, Germany

Ørsted pioneered SBJ foundations at Borkum Riffgrund 1 (2014) and expanded their use in Borkum Riffgrund 2 (2018), installing 20 SBJs.

Pros:

- Quiet and fast installation

- Removable and reusable—ideal for decommissioning

- Minimal seabed disturbance

Cons:

- Less proven at commercial scale

- Not suitable for all soil types

- Requires precise engineering and monitoring

- Not suitable for sites with seabed mobility

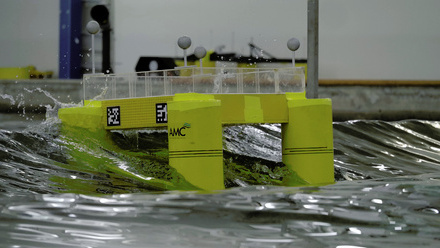

5. Floating foundations

Floating foundations are used in deep waters (typically over 60 meters) where fixed-bottom structures are impractical. They are anchored to the seabed with mooring lines and include designs like spar-buoys, semi-submersibles, and tension-leg platforms.

Case study: Hywind Scotland

Hywind Scotland, developed by Equinor, is the world’s first floating offshore wind farm. It uses spar-buoy floating foundations anchored in waters over 100m deep.

Pros:

- Unlocks vast new areas for wind development

- Easier to assemble and maintain in port

- Reduces visual impact from shore

Cons:

- Higher upfront costs and technical complexity

- Mooring systems and dynamic cables are still evolving

- Requires robust monitoring and maintenance

Each foundation type plays a vital role in expanding offshore wind capacity. As technology advances and projects move into deeper waters, innovation in foundation design will be key to unlocking the full potential of offshore wind energy.

The views in the article represent those of the author, and not necessarily of IMarEST.

Tell us what you think about this article by joining the discussion on IMarEST Connect.

To discuss this and similar topics, you can join the Offshore Renewables Special Interest Group.

Image: two of five floating wind turbines being prepared to sail off to Peterhead, Scotland, to establish the world's first floating wind farm, Hywind Scotland. Credit: Shutterstock